PP caps is short for pilfer proof caps which is anti-theft bottle caps and has a composite structure design that combines metal and plastic, mainly used for sealing and anti-counterfeiting of packaging containers such as wine and beverages.

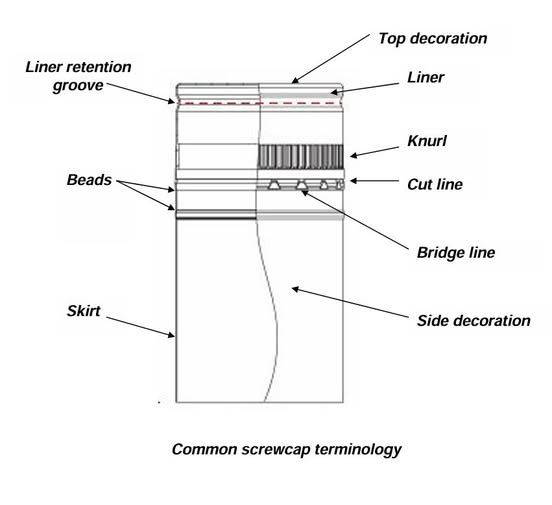

Aluminum PP caps full form are mainly composed of a few parts listed as:

1. Cover body:

- Material: Made of high-quality aluminum alloy materials, such as 8011-H14, 3105-H14 and other alloy states.

- Surface treatment: After electroplating, it has a beautiful appearance and good corrosion resistance.

- Dimensions: The thickness is generally 0.20mm-0.23mm, and the width is 449mm-796mm.

2. Anti-theft ring:

- Material: Made of high-strength aluminum also.

- Structural features: Located in the lower part of the bottle cap skirt, connected to the cap body through precise processing and welding. There are multiple "bridge points" between the anti-theft ring and the cap body to form an intermittent twist line.

3. Seal

- Seal design: The seal is usually located inside the aluminum PP caps and contacts the bottle mouth, ensuring that when the bottle cap is closed, it can effectively prevent liquid leakage and external contamination.

- Material: The seal is generally made of soft rubber or plastic materials to provide a good sealing effect.

4. Opening Mechanism

- Thread design: Many pilfer proof caps use a thread design for easy rotation and opening. The thread design should closely match the thread of the bottle mouth to ensure sealing.

- Press-on or flip-top: Some anti-theft bottle caps may also use a press-on or flip-top design to increase the convenience of use.

5. Appearance design

- Brand logo: The pp caps usually print the brand logo or product information to increase brand recognition.

- Color and pattern: The color and pattern design also takes into account the visual appeal of marketing and consumers.

6. Compatibility design

- Adapt to the bottle mouth: The design of the aluminum pilfer proof cap needs to match the size and shape of the specific bottle mouth to ensure the effectiveness of its function.

PP caps are mainly used in packaging fields with high requirements for sealing and anti-counterfeiting, such as high-end alcoholic beverages (such as liquor, wine), functional beverages, etc. The technical advantages including:

- Efficient sealing: Combining the characteristics of metal and plastic, adapting to temperature changes, and reducing the risk of wine leakage.

- Strong anti-counterfeiting: Anti-theft ring breakage and glass ball anti-refilling design, double protection.

- Simplified process: Compared with traditional multi-component bottle caps, the structure is simpler (only aluminum jacket, upper piece, transparent mouth, inner plug and other parts are required), and the assembly efficiency is high.

User experience: moderate opening torque, taking into account both sealing and ease of use.

The design of PP caps full form should not only take into account the anti-theft function, but also take into account sealing, ease of use and aesthetics. Through reasonable structural design, the safety of products can be effectively protected and the trust of consumers can be enhanced.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China