As a professional aluminum bottle cap manufacturer, we have constructed a six-fold quality inspection system covering the entire life cycle to ensure that each cap is delivered with zero defects from raw material to finished product.

Testing

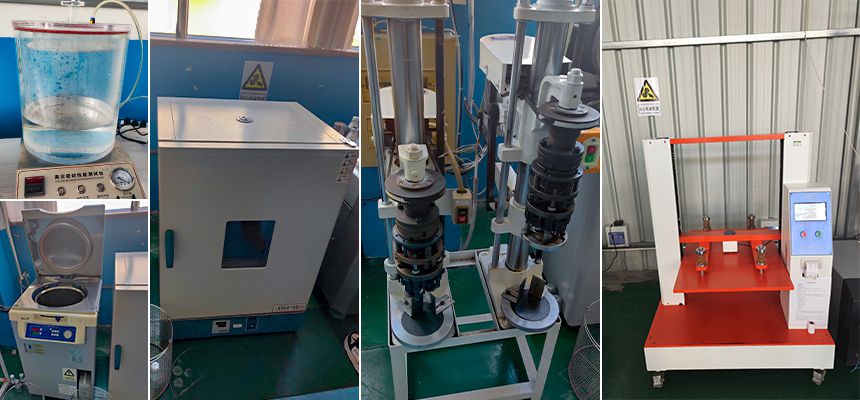

1. Bottle cap testing items

- Sealing test (test whether the surface of the cap is good after sealing)

- Twist-off force test (1.0 or less is more suitable, if the value is high, it is difficult to twist)

- Sealing test (for gas-free liquid, use water to invert and evacuate)

- Vapor tightness test (for gas-containing liquid, there are positive and negative pressure tests to test whether there is gas leakage)

- High temperature resistance test (90 degree high temperature resistance test, 121 degree high temperature resistance test)

2. Carton testing items

- Compression test (whether the carton breaks after the cap is installed)

- Vibration test (test whether it can withstand shaking)

MESSAGE

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China