Aluminum ROPP caps with EPE liner is a professional sealing solution widely used in wine, beverage and high-end food packaging, integrating anti-theft security, buffer protection and customized design.

Product structure and working principle

- Material and process:

Made of food-grade aluminum 3105 or 8011, formed by roll-on pilfer proof process, combined with anti-theft ring design, the ring will break when opened for the first time, realizing the anti-tampering function.

- Dimensions:

Common sizes include 28mm, 30mm (heights are 35mm, 50mm, 60mm, etc.), suitable for glass bottle mouth.

- Surface treatment:

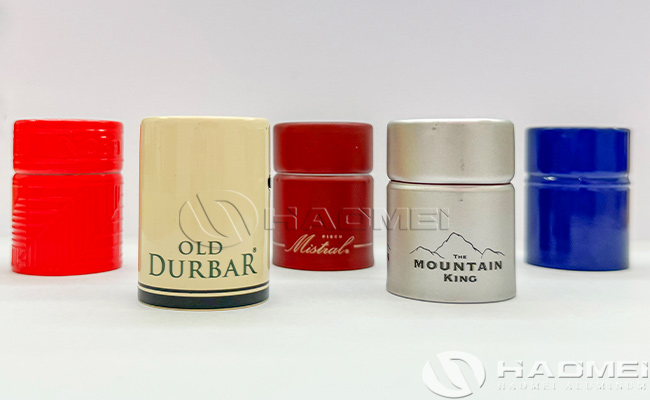

Supports lithography, hot stamping, UV coating, embossing and other processes to meet brand customization needs.

2. EPE liner (PE foam pad)

- Material properties:

Low-density polyethylene (LDPE) is physically foamed to form a closed-cell structure, which is impact-resistant (absorbs 90% of the falling energy), moisture-proof (IPX4 waterproof grade), temperature-resistant (-40℃ to +80℃) and food-grade safety (FDA certified).

- Functional design:

The lining fits the bottle mouth, and achieves an airtight seal through compression and resilience, blocking the intrusion of oxygen and moisture, and extending the shelf life of the contents.

Core features and advantages of aluminum ROPP caps with EPE liner:

1. Anti-theft and sealing

The ROPP structure ensures that the package has not been illegally opened, and the EPE lining provides a secondary sealing barrier, which is suitable for high-value alcoholic beverages (such as whiskey, liquor) and easily oxidized products.

2. Buffering and protection

The honeycomb structure of the EPE lining can withstand a compressive strength of 200N/㎡, and the breakage rate of a 1.5-meter drop is less than 0.5%, which is significantly better than traditional foam.

3. Customized adaptation capability

- Bottle cap: supports LOGO engraving and color customization.

- Lining: adjustable density (18-30kg/m³), shape (L-shaped corner guard, hexagonal honeycomb structure), and embedded with NFC chip or temperature-sensitive ink (over-temperature color warning).

4. Safety and environmental certification

Complying with ISO9001 and GB 4806.7 food safety standards, EPE materials can be recycled more than 5 times, and carbon emissions are 47% lower than traditional foam.

Industry application scenarios

Aluminum ROPP bottle caps with EPE lining are widely used in many industries, and the main uses include:

Wine industry: used for bottled wine, providing good sealing performance to prevent oxygen and external pollutants from entering.

- Spirits industry: suitable for various spirits bottles to ensure the freshness and quality of drinks.

- Beverage industry: used for bottled beverages, such as juice, soda, etc., to ensure the sealing and safety of beverages.

- Food industry: suitable for bottled condiments, edible oils, etc., which can effectively prevent food from spoiling.

- Cosmetics industry: used for some liquid cosmetics and skin care products to ensure the safety of products during storage and use.

- Pharmaceutical industry: used for the packaging of liquid drugs to ensure the effectiveness and safety of drugs.

When selecting aluminum ROPP caps with EPE liner, 30mm anti-theft cover + high-density EPE (density ≥ 25kg/m³) is the first choice for alcoholic drinks; 28mm cover + lightweight EPE can be used for beverages/water to reduce costs.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China