PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China

PRODUCT DETAILS

A screw cap is a metal cap that screws onto threads on the neck of a bottle, generally with a metal skirt down the neck to resemble the traditional wine capsule ("foil"). A layer of plastic (often PVDC), cork, rubber, or other soft material is used as wad to make a seal with the mouth of the bottle.

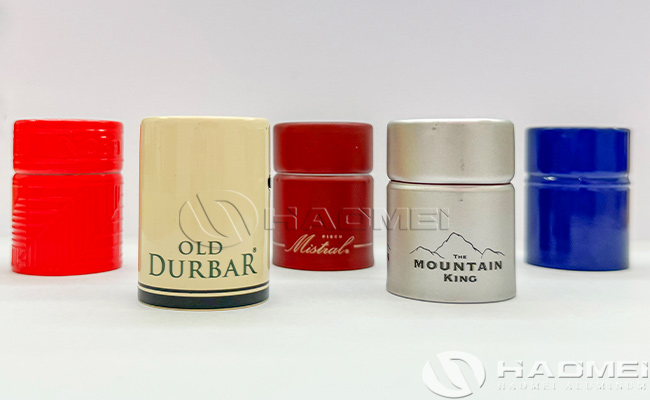

Aluminium screw caps are closures made from aluminium that are used to seal containers, jars and bottles. These caps are commonly found in the beverage industry, especially for products like wine, spirits, and non-alcoholic beverages, as well as in pharmaceuticals and food packaging. An aluminium screw cap for bottles and jars adds to your packaging solution while also giving it a high-end look.

Aluminum screw caps are mainly used for bottling spirits, closures with the dimensions 31.5×24mm and 31.5×44mm with olive oil pourers are also used for sealing olive oil and closures with 28×15.4mm with PVC compound can be used for bottling carbonated drinks.

Specification of Aluminium Screw Caps:

Aluminium Alloys | 1050, 1070, 3105, 8011 |

Liner Options | PE Foam, Composite Material, Pulp and Aluminium, Pulp and Polymer, Heat Seal, Pressure Sensitive, Plastic Sol |

Surface Finishes | Brushed Aluminium, Polished, Anodized, Lacquer Coating, Color Coating (Silver, Blue, Black, Gold, etc.) |

Diameter Range | 18 mm – 53 mm |

Common Sizes | 28x15 mm, 30x21 mm, 30x35 mm, 30x60 mm, 53-400, 24x400, 18x400mm, 20x400mm |

Thread Type | Continuous Thread (CT), Roll-On Pilfer Proof (ROPP), Push & Turn |

Customizations | Embossing, Debossing, Laser Engraving, Custom Logos |

Certifications | FDA Approval, EU Food-Grade Compliance, ISO Standards |

Cap Height Range | Short, Medium, Tall |

Compatibility | Glass Bottles, Plastic Bottles, Jars, Metal Containers |

Applications | Beverages, Wine, Food Products, Pharmaceuticals, Cosmetics, Personal Care, Olive Oils, Chemical Products |

Advantages of Aluminium Screw Caps:

*Decoration craft: We can offer the litographic printing,embossing , UV printing , hot foil and the silk screen

*Different liners:We also can offer different liner, such as the saranex, sarantin , PE liner, PE liner with QR code.

*Appearance: color can be customized,tear liner can be on the aluminum screw caps, It's easy to open for customers.

Decoration Craft of Aluminium Screw Caps:

Common Sizes of Aluminium Screw Caps:

Specification | Diameter | Total Height | Color | Liner |

18 | 18mm | 12/14/11mm | Silver, Gold, Black, Red, or Customized Colors. | PE, TPE, Rubber, Silicone, Aluminum Foil, Plastisol, Pressure Sensitive Liners. |

20 | 20mm | 12mm | ||

24 | 24mm | 13/15mm | ||

28 | 28mm | 13/15mm | ||

31 | 31mm | 14mm | ||

38 | 38mm | 11/13mm | ||

45 | 45mm | 13mm | ||

52 | 52mm | 13mm | ||

53 | 53mm | 13mm |

The Features of Aluminium Screw Caps:

- Leak-proof: aluminium caps can be perfectly airtight thanks to an EPE liner! EPE liners help to compensate for the rigidity of the metal by perfectly joining the edges of the bottles and jars.

- Recycling: aluminium caps are 100% recyclable. In addition, the metals already contain some recycled material, for the most part. These metal caps are thus perfectly in line with an eco-friendly approach!

- Customisable: aluminium caps can be customised by embossing. This customisation will give your finished product a unique look.

- Aesthetic: Aluminium caps are appreciated for their design. The look of brushed aluminium can also be used to give your product an authentic or modern touch. These caps are often used by high-end brands to highlight their positioning.

Manufacturing Process

Stamping: Aluminium sheets are processed into the initial bottle cap shape through stamping equipment.

Thread Processing: Professional molds are used to process threads on the bottle caps, ensuring compatibility with the bottle mouth.

Surface Treatment: Spraying, anodizing, or printing processes are performed according to requirements.

Sealing Gasket Assembly: Sealing gaskets are installed for specific purposes to enhance leakage prevention.

Quality Check:

Testing

1. Bottle cap testing items

- Sealing test (test whether the surface of the cap is good after sealing)

- Twist-off force test (1.0 or less is more suitable, if the value is high, it is difficult to twist)

- Sealing test (for gas-free liquid, use water to invert and evacuate)

- Vapor tightness test (for gas-containing liquid, there are positive and negative pressure tests to test whether there is gas leakage)

- High temperature resistance test (90 degree high temperature resistance test, 121 degree high temperature resistance test)

2. Carton testing items

- Compression test (whether the carton breaks after the cap is installed)

- Vibration test (test whether it can withstand shaking)

MESSAGE

RECOMMENDED PRODUCTS