PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China

PRODUCT DETAILS

Liquor bottle caps refers to the caps used to seal spirits (such as whisky, vodka, rum, white wine, etc.), which usually combine the functions of sealing, anti-counterfeiting and brand display. The material is mainly aluminum (including screw cap, crown cap, etc.), and some high-end spirits may be combined with cork or ceramic caps.

Liquor bottle caps structure consist of an aluminum housing and an internal sealing layer such as a food-grade plastic or silicone gasket. Aluminum is lightweight, corrosion-resistant and easy to shape, allowing for precise threading to ensure a tight seal. Some high-end liquor caps also incorporate tamper-evident rings or reusable silicone membranes (e.g. screw caps adapted to the Coravin system, which can be stored for up to 3 months after opening).

Liquor Bottle Caps Sizes:

Size | Data | Description |

Diameter | 24mm | Suitable for small neck design, mostly found in traditional spirits bottles (e.g. some whisky, vodka) |

24mm | Widely used in modern spirits bottles, adapted to standard bottle tops, providing better sealing and anti-theft properties. | |

Height | Typically 18-60mm | Taller than wine bottle caps for stronger seals |

Thickness | Aluminum thickness 0.20-0.26mm | Some caps with high sealing requirements may be thicker, taking into account both strength and processability. |

Design of Liquor Bottle Caps:

- Surface treatment

Enhanced anti-counterfeiting and aesthetics through embossing, hot stamping, silk-screening and other techniques .

- Anti-theft design

Twist-off/open structure: the connecting point line breaks after the cap is opened, displaying the anti-theft symbol and preventing secondary encapsulation.

Destructive inner liner: the inner cushion is made of special dripping material, which cannot be recovered after opening to ensure the sealing.

- Sealing structure

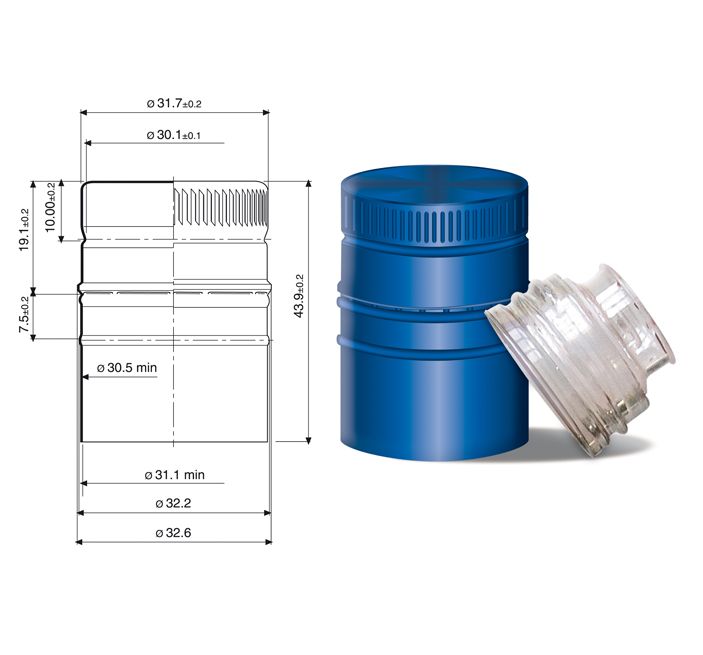

Radial fit tolerance: the gap between the inner diameter of the aluminum cap and the outer diameter of the bottle mouth is controlled at 0.3-0.4mm to avoid sealing problems caused by too loose or too tight.

Axial Height Tolerance: Ensure that the cap fits tightly in the height direction of the bottle mouth to prevent leakage.

Finish of Liquor Bottle Caps:

Parameter | Specification |

Sizing | Roller Coating Vinyl base size |

Inside gold | Roller Coating Full lacquer gold |

Outside printed as per customer requirement | Flaxo print |

Varnish | Roller Coating PP cap Transparent Varnish |

Decoration | |

Top | lithographic printing / embossing / UV printing / hot foil / silk screen |

Side | four colors offset printing / embossing / hot foil / silk screen printing |

Typical Application of Liquor Bottle Caps:

Liquor Category | Typical Application Scenarios | Cap Features |

Whisky | Single malt whisky, blended whisky, cask strength whisky, etc. | Mostly with 28mm diameter cap, matte or metallic surface, with hot stamping/laser engraving, reflecting high-end positioning. |

Vodka | Neutral liquor, flavored vodkas (e.g. lemon, vanilla) | Sealability is important, commonly 24mm or 28mm caps, some brands use a transparent window to show the purity of the liquor. |

Rum | White Rum, Gold Rum, Black Rum | Tropical style designs (e.g. embossed palm leaf pattern), aluminum cap liners need to withstand high humidity environments. |

Tequila | Silver Label Tequila, Aged Tequila (Añejo) | Commonly used with 28mm caps, some Mexican brands have colored aluminum caps with traditional ornamentation. |

Brandy/Cognac | VSOP, XO grade Cognac | High-end market prefers gold/rose gold plated aluminum caps with cork assisted sealing (double seal construction). |

Liqueurs | Sweet liquors (e.g. Baileys, Cointreau) | Small diameter bottles (24mm cap mostly), the liner needs to be resistant to sugar corrosion to prevent sticking. |

Other Spirits | Gin, Vermouth, Chinese White Wine (some high-end series) | The white wine sector is gradually replacing the traditional plastic cap, emphasizing anti-counterfeiting (e.g. one cap, one code). |

Core Advantages of Liquor Bottle Caps:

- Sealing performance

Aluminum screw cap: precision threaded design isolates oxygen and prevents evaporation or oxidation of liquor (e.g. whisky for long term storage).

Lining material: Silicone or PVC gasket to enhance sealing, suitable for high alcohol concentration liquids (e.g. white wine above 60% vol).

- Anti-counterfeiting and security

Anti-theft ring design: cap body breaks after opening the bottle to prevent secondary filling.

Laser engraving/QR code: integrated brand logo or traceability information to combat counterfeit wine (e.g. Moutai anti-counterfeiting cap).

- Brand display and customization

Surface technology: can be plated, painted, embossed or printed with logos (e.g. personalized caps for Absolut Vodka).

Shaped design: customized special shapes (e.g. hexagonal, embossed pattern) to enhance the high-end feeling.

- Environmental protection and cost

Aluminum is recyclable, more resistant to moisture and insects than cork, and suitable for mass production.

The overall cost is lower than the combination of cork + tin foil closure (especially for mid-range spirits).

- Bottle opening experience

Screw caps are tool-less and ready to drink, suitable for ready-to-drink consumption scenarios (e.g. pre-mixed cocktails).

Some high-end caps are designed to be re-sealable (e.g. screw caps with silicone plugs), which prolongs the preservation time after opening.

Packaging of Aluminum Liquor Caps:

Parameter | Specification |

Quantity | According to the caps sizes |

Packing box | 5 ply or 7 ply Body Corrugated Boxes according to the requirement of customer. |

Packing – Inner | Packed in sealed Polyethylene bags |

Packing – External | Gum tape and strapped with PVC straps |

Optional | Palletize as per Customer requirement. |

MESSAGE

RECOMMENDED PRODUCTS