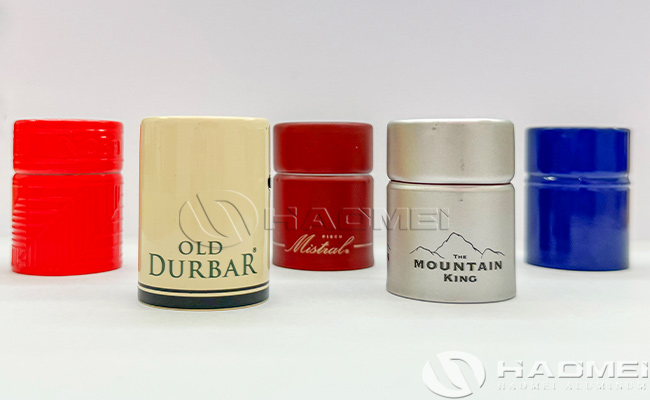

Printed aluminium ROPP caps produce obvious destructive marks when opened, ensuring that consumers can confirm that the product has not been tampered with. Aluminum materials provide good sealing performance and can effectively prevent liquid leakage and external contamination. Printing can be performed according to customer needs, including brand logos, product information, pattern designs, etc., to enhance the market competitiveness of products.

Key elements of customization of aluminium ROPP caps:

1. Material selection:

The base material is mostly 3000 series aluminum (such as 3105) or 8000 series aluminum alloy (such as 8011). The former has good ductility and the latter has strong corrosion resistance, which is suitable for different scene requirements. Some high-end products use 5000 series aluminum-magnesium alloy to enhance structural strength and are suitable for pharmaceutical packaging with high sealing requirements.

2. Printing process:

- Thermal transfer technology: It can print complex patterns, has high weather resistance, and is suitable for outdoor product packaging (such as beverage bottle caps).

- Multi-color printing anti-counterfeiting technology: multi-color printing aluminium ROPP cap realizes anti-counterfeiting logos through UV electroplating and alumina printing to enhance brand security.

- Laser engraving: used for personalized logos or limited edition designs, such as exclusive patterns on wine bottle caps.

3. Functional customization:

- Anti-theft design: such as twist-off or pull-ring structures to ensure the integrity of the package before opening.

- Sealing enhancement: through the lining of PE rubber pads or composite films, the barrier to oxygen and moisture is improved, suitable for long-term storage of food and medicine.

Production process and technical requirements of printed aluminium ROPP caps:

1. Design stage:

- Customize the thread structure according to the bottle mouth size (such as diameter 30-70mm, height 10-40mm) to optimize the opening experience.

- A vector file of the printed pattern is required to support Pantone color card matching to ensure color consistency.

2. Production stage:

- Use stamping technology and cooperate with precision molds to achieve efficient mass production.

- Surface treatment includes oxidation, lamination or spraying to enhance wear resistance and corrosion resistance.

3. Quality control:

- Comply with FDA (food contact materials) or ISO9001 standards, and pass tensile strength (1-28N/mm²) and chemical resistance tests.

- Some printed aluminium ROPP caps manufacturers provide UL/CUL certified products to meet export requirements.

Application scenarios and market trends of aluminium ROPP caps:

- Food and beverages: Beer, juice and other products that require high sealing, customized printing can be combined with brand IP or holiday themes.

- Medicines and health products: require sterility and moisture resistance, often use monochrome printing + anti-counterfeiting logos, such as cartoon pattern design for children's medicines.

- Cosmetics: high-end brands tend to metal texture + embossing technology, such as the three-dimensional pattern of perfume bottle caps.

In short, custom printed aluminium ROPP caps can not only enhance the brand image of the product, but also effectively protect the safety and quality of the product, which is an ideal choice for many industries.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China