Aluminum ROPP (Roll-On Pilfer Proof) caps are widely used for sparkling water and other beverage packaging. They are designed to provide a strong seal and anti counterfeiting properties, ensuring that beverages are resistant to leakage and tampering during transportation and storage. The aluminium ROPP cap mechanically interlocks with the bottle neck through a molded gasket, creating a multi-layered seal that effectively blocks oxygen and microbial intrusion, extending the shelf life of sparkling water.

The aluminum ROPP cap is rolled to fit snugly over the bottle threads. Combined with a food-grade liner (such as PE or Saranex), it creates a double seal that can withstand internal pressures of 3-6 bar, effectively preventing CO2 leakage and ensuring consistent carbonation and taste for sparkling water. For example, Pelliconi's 28x15mm ROPP cap is specifically designed for sparkling beverages. It features a PVC-free liner, is pasteurized and hot-fill compatible, and is suitable for both glass and PET bottles. Aluminum has a low density (approximately 2.7g/cm³), and each cap weighs only about 4g, making it easy to transport and store. Aluminum is also highly corrosion-resistant, resisting the slightly acidic environment of sparkling water and preventing rust and odor transfer. Aluminum surfaces can be created with high-resolution patterns and colors through screen printing, hot stamping, and embossing, supporting custom logos, QR codes, and other marketing elements.

Sparkling water generates high pressure (typically up to 90 PSI) due to the dissolved carbon dioxide within, necessitating the use of a stronger aluminum material. Preferred aluminum alloys are 8011 (easy to process and corrosion-resistant) and 3105 (high-strength), with a thickness of 0.20-0.30mm and food contact safety standards. Lining material selection depends on the application: PE is used for general sealing, while Saranex (polyvinylidene chloride) provides a higher moisture vapor barrier and extends shelf life.

Mainstream Sizes of Aluminum ROPP Cap for Sparkling Water:

1. 28mm Aluminum ROPP caps Diameter Series

- 28x15mm:

This is the most classic sparkling water size, widely used by international brands such as Perricone. The ROPP cap has a 15mm height and is compatible with MCA1 and MCA2 neck types. It achieves a pressure seal of 3-6 bar through a rolling process and is suitable for both glass and PET bottles.

- 28x18mm:

The 3mm increase in height enhances structural stability and is commonly used in hot-fill processes requiring a tighter seal (e.g., pasteurization to 121°C). Some suppliers offer a segmented tamper-evident band for enhanced anti-counterfeiting.

- 28.7x17.7mm:

This cap meets European standard sizes (e.g., GPI 1650 neck finish). It features a 17.7mm cap height and a TPE liner, compliant with EU Food Contact Regulation EC 1935/2004.

2. 30mm Diameter Series

- 30x18mm:

This size is suitable for medium-volume bottles under 38mm, commonly used for high-end sparkling water or fruit-based beverages.

- 30x31mm:

This custom-made model features a significantly increased cap height. It's used in applications requiring extended thread engagement (such as beer bottles) and can withstand higher internal pressures.

3. Other Common Specifications

- 20x14mm:

Designed for small-diameter bottles (such as 100ml beverages), it features a 14mm cap height and a lightweight design (weighing only 2.5g per bottle), making it suitable for children or portable applications.

- 24x18mm:

This model fits glass bottles with a 24mm neck, commonly found on imported sparkling water (such as Italian San Pellegrino). It features an 18mm cap height and uses lead-free ink for brand logo printing.

Manufacturing Process of Aluminum ROPP Cap for Sparkling Water:

- Coil Processing:

After uncoiling, cleaning, and coating (primer and topcoat), the aluminum coil is formed into cup-shaped blanks through a continuous stamping process.

- Thread Rolling:

The blanks are threaded on a rolling press, and then the liner and tamper-evident tape are installed.

- Decorative Printing:

The aluminium ROPP cap surface is printed using offset or pad printing techniques. Some processes support UV curing for enhanced wear resistance.

Advantages of aluminum ROPP caps used for sparkling water bottles:

- Sealing:

Aluminum ROPP caps effectively prevent gas and liquid leakage, ensuring that sparkling water retains its bubbles for longer.

- Anti-Counterfeiting:

The cap's design leaves a visible mark when opened, allowing consumers to verify that the product has been opened by observing the integrity of the cap.

- Lightweight:

Aluminum is relatively lightweight, which helps reduce shipping costs and reduces the burden on the environment.

- Recyclability:

Aluminum is recyclable, aligning with sustainable development requirements, and more and more consumers are choosing environmentally friendly packaging.

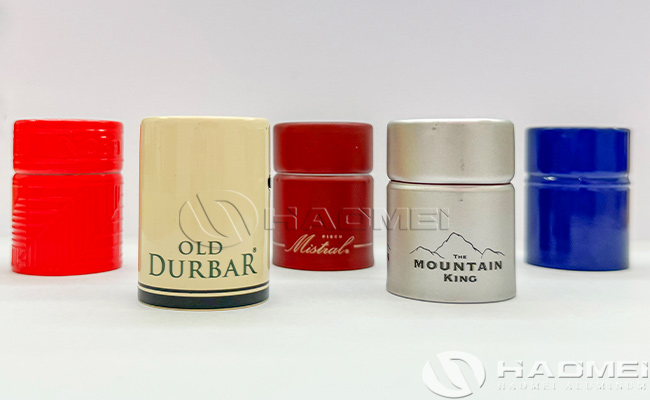

- Aesthetics:

Aluminum bottle caps can be treated with a variety of surface treatments and printings, offering a wide range of design options that enhance the product's appearance and market competitiveness.

The production of aluminum ROPP caps for sparkling water must comply with national standards. Key testing items include:

- Sealing performance:

Leakage is ensured through inversion inspection at normal pressure, heat resistance testing, and 800kPa pressure holding tests.

- Opening performance:

Opening torque is measured and vertical cut fractures are inspected to ensure smooth opening.

- Appearance quality:

The surface must be smooth and free of stains, with a coating hardness of 3H or higher, and the printed pattern must be clear and free of missing prints.

- Hygiene standards:

Materials and additives must comply with food safety standards.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China