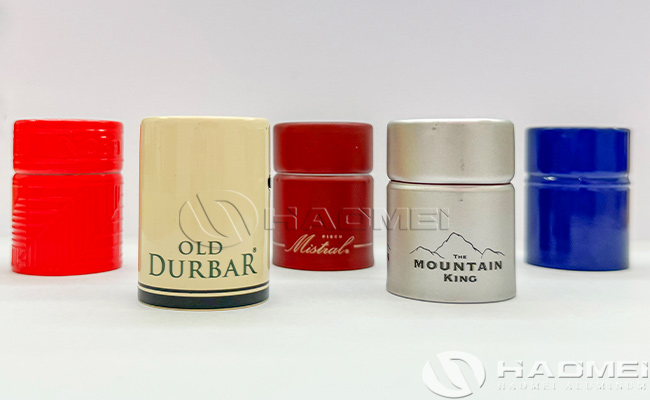

Pilfer proof aluminium closures are packaging components that combine sealing, anti-theft and decorative functions. They are widely used in food, beverage, pharmaceutical and chemical industries. The core advantages of aluminium pilfer proof closure caps lie in their lightweight material, strong sealing properties, manageable costs, and recyclability. Furthermore, their unique structural design provides a "one-time opening" anti-theft effect.

Pilfer proof aluminium closure caps are commonly used for packaging beverages, pharmaceuticals and other liquid products to prevent unauthorized opening and theft. The core design of these pilfer proof aluminum bottle caps lies in their locking ring (anti-theft ring) and bridge point structure. The lower section of the cap skirt is formed through a rolling process with intermittent twist lines, connecting the anti-theft ring to the main body of the cap via several "bridge points." When the consumer twists the cap to open, the bridge points break, and the anti-theft ring is retained on the neck flange, leaving a visible opening mark and providing the anti-theft function.

The aluminium pilfer proof caps are primarily made of aluminum alloys 8011-H14 and 3003-H16, with thicknesses ranging from 0.20-0.23mm and widths ranging from 449-796mm. Material selection was based on the following properties:

- Lightweight:

Aluminum has a density of 2.7g/cm³, only one-third that of iron, reducing transportation costs.

- Corrosion Resistance:

Aluminum oxide naturally forms a film (thickness ≥ 6μm) on the surface, is acid and alkali resistant (pH 2-9), and resistant to aging (tensile strength change ≤ 20% after 70°C/72h hot air aging).

- Processability:

Elongation ≥ 3%, allowing for stamping into complex structures (such as anti-theft rings and threads), while maintaining high surface flatness (no rolling marks or scratches).

- Environmental Protection:

Aluminum is 100% recyclable, complying with circular economy requirements.

- Sealing:

Bottle caps are typically equipped with a gasket (such as EVA, PE, or silicone). Combined with the plasticity of aluminum, they fit snugly around the bottle opening, effectively blocking air, moisture, and dust, while preventing contents from leaking and extending product shelf life (e.g., preventing beverages from leaking or lubricants from getting wet).

- Advantages over plastic caps:

High-temperature resistance (retorting and sterilizing at 121°C) and no risk of plasticizer precipitation. It offers excellent printing adaptability, supports multi-color overprinting, and supports laser engraving, enhancing brand recognition.

Common dimensions for pilfer proof aluminium closures vary depending on the application scenario and product type. Here are some common dimensions:

25.6×17.0mm

28.6×21.0mm

30.6×21.0mm

31.0×24.5mm

29.3×35.0mm

30.9×60.0mm

- Soft drink bottle caps:

28.2×15.4mm

28.2×17mm

- Other beverage and functional drink bottle caps:

28×15.5mm

31.5×18mm

28×18mm

38×18mm

In addition, other common sizes include 20mm, 24mm, and 30.6×24mm.

Main application areas of pilfer proof aluminium closures:

- Alcoholic Beverage Packaging:

Accounting for 50% of the market share, this product is used for sealing bottles of liquor, wine, and beer, with an annual demand exceeding 4.5 billion units.

- Pharmaceutical Packaging:

Aluminum-plastic combination caps (aluminum cap + plastic inner plug) are widely used in infusion bottles and vaccine bottles, meeting aseptic sealing requirements.

- Beverage Packaging:

Carbonated beverage caps must pass a 1207 kPa pressure test, while non-carbonated beverage caps prioritize ease of opening (torque ≤ 1.5 N·m).

Pilfer proof aluminium closures are a packaging solution widely used in food, beverage, and pharmaceutical applications. Their core function is to ensure product sealing and safety through an irreversible opening mechanism. By integrating material science, precision manufacturing, and structural design, they achieve a balance between functionality and cost-effectiveness.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China